Next Generation Bipolar Plates for Automotive PEM Fuel Cells

Por um escritor misterioso

Last updated 01 junho 2024

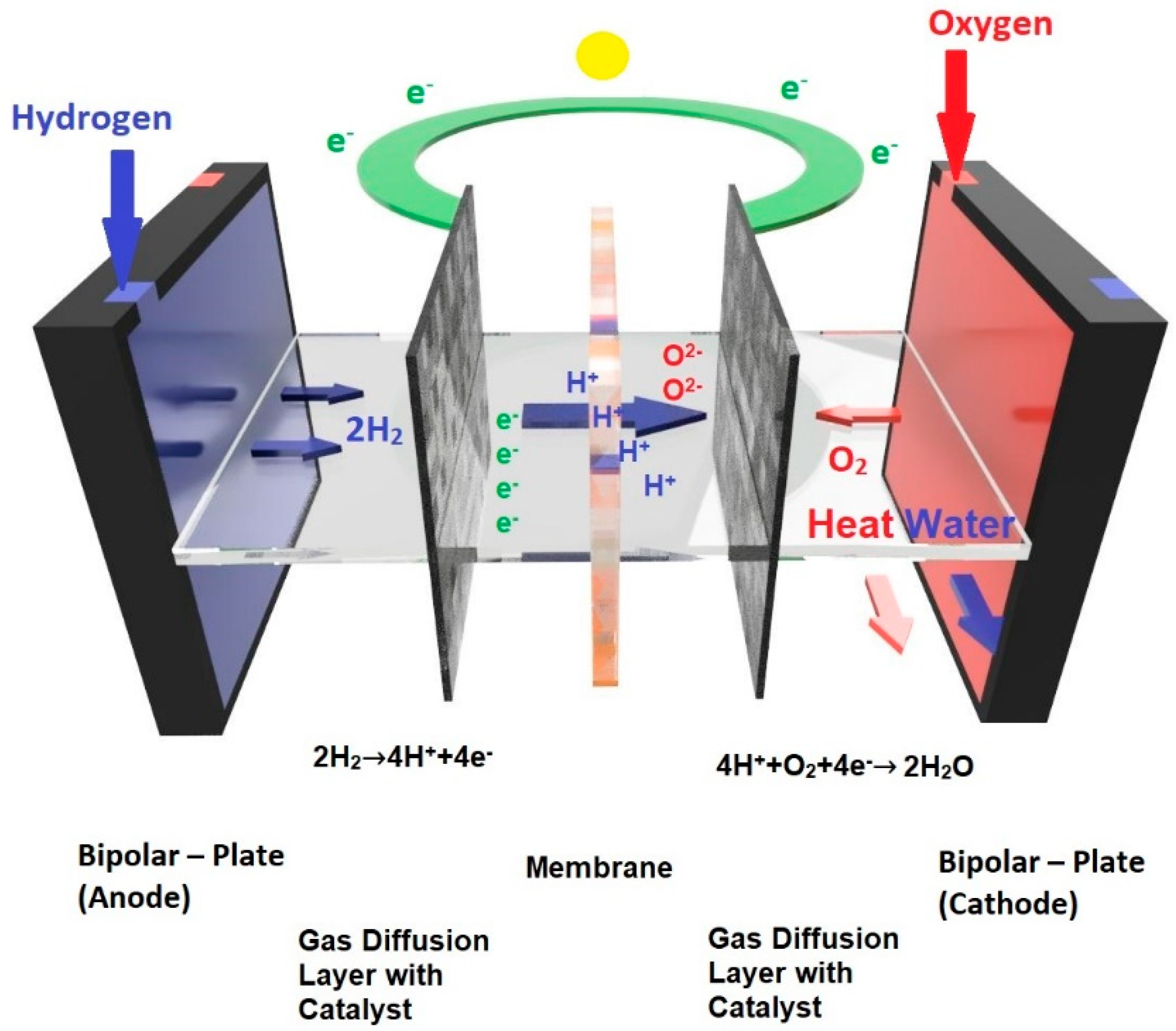

The results of a successful U.S. Department of Energy (DoE) funded two-year $2.9 MM program lead by GrafTech International Inc. (GrafTech) are reported and summarized. The program goal was to develop the next generation of high temperature proton exchange membrane (PEM) fuel cell bipolar plates for use in transportation fuel cell applications operating at temperatures up to 120 °C. The bipolar plate composite developed during the program is based on GrafTech’s GRAFCELL resin impregnated flexible graphite technology and makes use of a high temperature Huntsman Advanced Materials resin system which extends the upper use temperature of the composite to the DoE target. High temperature performance of the new composite is achieved with the added benefit of improvements in strength, modulus, and dimensional stability over the incumbent resin systems. Other physical properties, including thermal and electrical conductivity of the new composite are identical to or not adversely affected by the new resin system. Using the new bipolar plate composite system, machined plates were fabricated and tested in high temperature single-cell fuel cells operating at 120 °C for over 1100 hours by Case Western Reserve University. Final verification of performance was done on embossed full-size plates which were fabricated and glued into bipolar plates by GrafTech. Stack testing was done on a 10-cell full-sized stack under a simulated drive cycle protocol by Ballard Power Systems. Freeze-thaw performance was conducted by Ballard on a separate 5-cell stack and shown to be within specification. A third stack was assembled and shipped to Argonne National Laboratory for independent performance verification. Manufacturing cost estimate for the production of the new bipolar plate composite at current and high volume production scenarios was performed by Directed Technologies Inc. (DTI). The production cost estimates were consistent with previous DoE cost estimates performed by DTI for the DoE on metal plates. The final result of DTI’s analysis for the high volume manufacturing scenario ($6.85 /kW) came in slightly above the DoE target of $3 to $5/kW. This estimate was derived using a “Best Case Scenario” for many of the production process steps and raw material costs with projections to high volumes. Some of the process improvements assumed in this “Best Case Scenario” including high speed high impact forming and solvent-less resins, have not yet been implemented, but have a high probability of potential success.

Bipolar Plates: Carbon or Metal for PEM Fuel Cells? [Infographic]

Fundamentals, materials, and machine learning of polymer

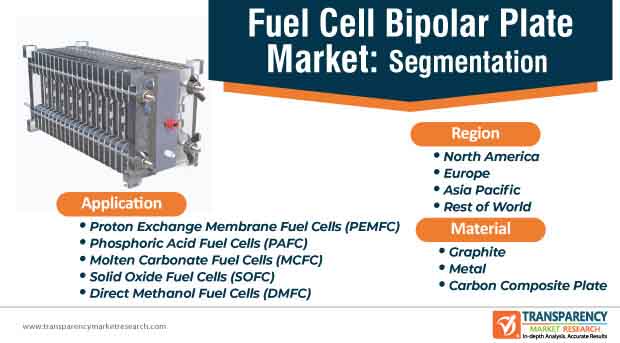

Fuel Cell Bipolar Plate Market

A comprehensive comparison of state-of-the-art manufacturing

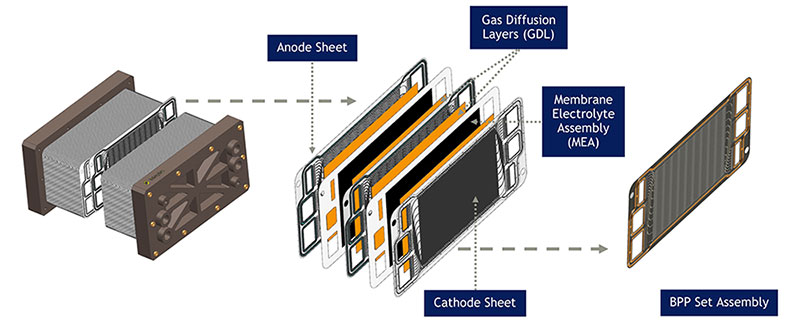

Basic structure of typical integrating PEMFC stack with end plate

Stainless steel bipolar plates for proton exchange membrane fuel

资源 Bipolar Plates and Their Critical Role in Fuel Cells

Materials, Free Full-Text

Ballard announces plan to scale production & reduce costs of next

More power, new design: Schaeffler develops next-generation

Recomendado para você

-

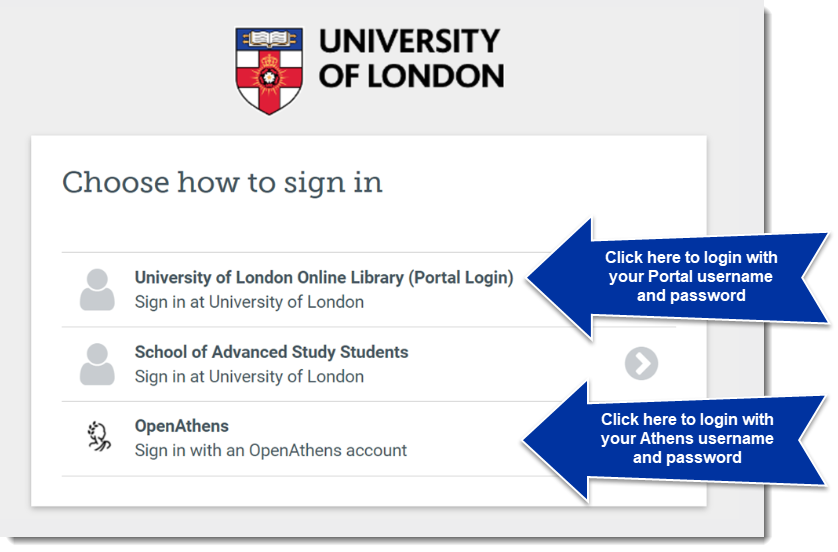

How do I login? The Online Library01 junho 2024

How do I login? The Online Library01 junho 2024 -

Utah's Online School Library01 junho 2024

-

Distance and online learning01 junho 2024

Distance and online learning01 junho 2024 -

Utah's Online Library – Granite Media01 junho 2024

Utah's Online Library – Granite Media01 junho 2024 -

The University's library resources include books, journals and e01 junho 2024

The University's library resources include books, journals and e01 junho 2024 -

Open and Free Access Materials for Research01 junho 2024

Open and Free Access Materials for Research01 junho 2024 -

Using the library The Warburg Institute01 junho 2024

-

Stream episode Digital Pathology Implementation at UoL Health by01 junho 2024

Stream episode Digital Pathology Implementation at UoL Health by01 junho 2024 -

![Miami gazette [1923-11-07 through 1924-03-05] - Magazines](https://digital.cincinnatilibrary.org/iiif/2/p16998coll14:9008/full/730,/0/default.jpg?page=48) Miami gazette [1923-11-07 through 1924-03-05] - Magazines01 junho 2024

Miami gazette [1923-11-07 through 1924-03-05] - Magazines01 junho 2024 -

Research that matters: setting guidelines for the use and01 junho 2024

Research that matters: setting guidelines for the use and01 junho 2024

você pode gostar

-

Modelo de TTK Gringa.x do CapCut01 junho 2024

Modelo de TTK Gringa.x do CapCut01 junho 2024 -

Rušewe01 junho 2024

Rušewe01 junho 2024 -

Sagger Anti-Tank Missile vs M60 Main Battle Tank: Yom Kippur War 1973: Duel Chris McNab Osprey Publishing01 junho 2024

Sagger Anti-Tank Missile vs M60 Main Battle Tank: Yom Kippur War 1973: Duel Chris McNab Osprey Publishing01 junho 2024 -

Teaser do episódio especial de 'Hora de Aventura' em stop-motion01 junho 2024

Teaser do episódio especial de 'Hora de Aventura' em stop-motion01 junho 2024 -

Como montar um salão de beleza pequeno?01 junho 2024

Como montar um salão de beleza pequeno?01 junho 2024 -

Portuguesas continuam com possibilidades de chegar ao Eurobasket2023 - BOM DIA Luxemburgo01 junho 2024

Portuguesas continuam com possibilidades de chegar ao Eurobasket2023 - BOM DIA Luxemburgo01 junho 2024 -

Duas sorveterias brasileiras estão entre as melhores do mundo01 junho 2024

Duas sorveterias brasileiras estão entre as melhores do mundo01 junho 2024 -

Delicioso pastel de vainilla decorada en merengue italiano01 junho 2024

-

BH GAMES - A Mais Completa Loja de Games de Belo Horizonte - Call of Duty: Modern Warfare III - PS501 junho 2024

BH GAMES - A Mais Completa Loja de Games de Belo Horizonte - Call of Duty: Modern Warfare III - PS501 junho 2024 -

GiveMeSport - Mbappe on his perfect player: I would choose01 junho 2024